The Story in pictures of a very sad Volvo Penta AQ145 |

|

|

Engine as taken from boat.

|

|

|

|

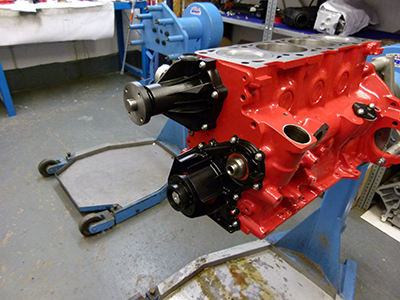

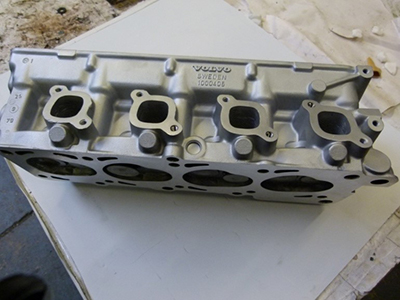

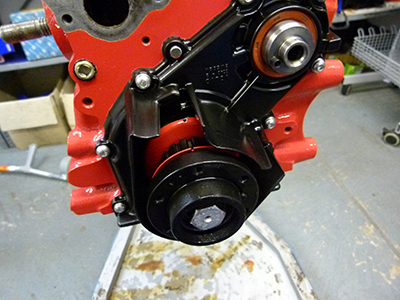

If this had been a current engine it would have been “Scrapped” but as a early 1980’s Volvo Penta AQ145, scrapping was not an option. THE SAME VOLVO PENTA AQ145 BEING RESTORED BY SWAYMAR ! |

|

|

All Pulleys and Dress up Items Shot Peened, Acid Etch Primed, Two Pack painted and Oven Baked Ready for Assembly. |

|

|

|

The Engine Progresses |

|

|

|

|

|

|

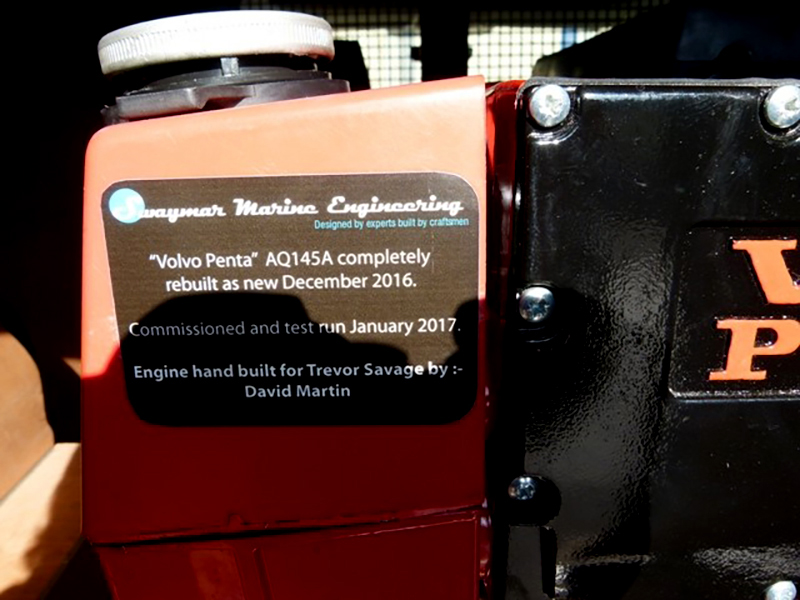

SWAYMAR finished item ready to be returned to a very happy customer who had really thought his engine was dead. |

|

|

|

“EAT YOUR HEART OUT VOLVO PENTA, IT LIVES BETTER THAN EVER” |

|

Reverse Direction "Riva" |

|

|

Some of the top quality, much stronger than standard components

|

|

|

|

These are the gears we made to enable us to make 2 x new engines for a famous “RIVA” where one engine needed to be reverse rotation, together with the conventional chain drive for the standard rotation engine. Using gears allowed us to build an engine where the crank assembly was reverse rotation, but the cam, distributor and oil pump were standard rotation items. |

|

|

Reverse direction "RIVA" finished, test run, set up and ready to ship out to Devon. |

MBY Articles - Click to Enlarge

Mercruiser Pin

A customer recently contacted us with a problem that, apparently I am told, is a very common problem with all Mercruiser legs both Bravo and Alpha of around the 1990’s era.

The steering pin is made of steel, not stainless, and only has a very flimsy seal where it goes through the transom shield. When the part of the pin outside the transom shield starts to rust it tears the seal up and allows the sea water to rust the pin above the seal which destroys the bearing and allows water into the boat.

Unfortunately the fix involves removal of the engine and leg, to get at and remove the transom assembly and the bad news is it doesn’t end there! if the rust has built up too much, removing the old pin can be a nightmare. In this case after a couple of hours trying to get it out with a slide hammer (it should just slide in) the actual casting broke and had to be replaced and it is not cheap !

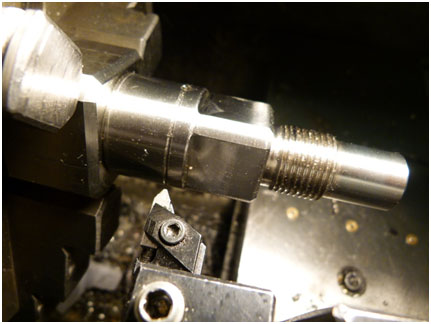

If the pin does come out the minimum requirement is a new pin with 2 x bearings, 2 x special washers and a new nut, at well over £400. We decided it was ridiculous to go down this route every 3-4 years, modification was the order of the day. I got a new pin made in Stainless Steel plus all the required Mercruiser bearings, washers and nut.

I then drilled a central hole down through the stainless steel pin to level with the lower bearing, and cross drilled through the bearing area to join up with this hole, and then turned a small groove around the bearing area across the bisecting holes, please note the above has to be done very carefully not to break off a drill in it. Stainless Steel is not easy to machine and a broken off drill will scrap it.

Stage two was to drill down through the top of the transom casting and tap it and fit a Stainless steel grease nipple, this now allows a grease gun to be used to pump waterproof grease to the top bearing, then down through the pin to the lower bearing from where it then fills in below the lower bearing and down to the seal. A few pumps every so often with a grease gun and it should last for years and save a fortune. Indecently, I was so pleased with the result that we decided to offer a kit of all the required parts including the S/S grease nipple to our customers at a better price than you can get the Mercruiser pin on its own.

IS CHEAP BOATING POSSIBLE? WE THINK FOR SOME YES !!!

Here at Swaymar we are constantly looking for ways to improve the boating experience. Top of the list has to be “make running costs cheaper”, and with us this is always a priority.

Our entire range of “Performance Enhanced Engines” has been designed and developed to give better fuel economy at any given constant speed by seriously increasing BHP, and in a boat, far more importantly torque by increasing efficiency, especially in the low and mid range. This allows the use of coarser pitch props which means you are using less RPM to maintain the same speed as before, less RPM = less fuel burned.

Sadly however it is a fact of life that no amount of development is ever likely to get petrol consumption down to that of an equivalent diesel engine. Therefore is diesel the answer, and also is it the only alternative route to go. Before answering let’s look at a few of the pro’s and con’s that most diesel engine suppliers tend to play down.

Let’s take a theoretical example, Mr “A” needs an engine for his boat rated at approx 330/350 BHP (this is a good figure as it is covered by both big block and small block petrol engines, and also diesel engines.)

At this maximum output the diesel will be using approx 16-18 gallons per hour, (approx £ 77)at the same output a petrol engine will consume around 23-25 gallons per hour (approx £ 104), at full chat the diesel uses approx £27 per hour less fuel, WOW ! no contest, let’s all get one !!!

BUT JUST HANG ON A MINUTE, let’s look a bit deeper, firstly purchasing an engine. A petrol engine in that power bracket will come out at around £ 7000, a diesel around £25000 almost 4 times the price the difference being £ 18000 this means that you will have to run your diesel engine at full throttle for 667 hours (a full month 24/7) to even reach the breakeven point, not many people will clock up 667 hours in 10 years and in any case at 667 hours many marine environment engines will need a rebuild ( and we will come back to that in a minute ).

We all know that in boats, weight is a major factor, so, a 330/350 BHP small block petrol engine complete weighs in at 575 lbs. (.2875 of a ton, 4 average people) a similar output diesel is listed at 1556 lbs (.778 of a ton,11 average people) almost 3 x the weight.

Typically a diesel engine in this bracket will have a maximum RPM of 3500 so it has an effective range of 700-3500 RPM = 2800 RPM a similar output petrol engine will have a maximum RPM of 5200 so it has an effective range of 700-5200 = 4500 RPM. Whilst this is totally irrelevant in a car, cars have more than one gear, BOATS DON’T ! so if you select a prop that will give your diesel boat a top speed of 35 knts it will struggle to keep at 5 knts pottering round the harbor. Select a prop to give your petrol boat (which is half a ton lighter) a top speed of the same 35 knts and it will purr around beautifully at 5 knots. It has a wider power band which is perfect for one gear. Why do you think that the average large diesel truck has between 10 and 15 gears (some have up to 18 gears)

Whilst diesel in a car, used almost daily is fine, left for months at a time in a tank it will grow serious bacterial junk in it which will require serious expense to remove, dispose of and put right any mechanical damaged parts. Petrol left in a tank for the same time will, at worst drop your power by 5% or so.

When at the end of 667 hours your economical diesel engine (which at this point has only broken even with the petrol engine costs anyway) does need a rebuild you could probably buy the best part of 2 x complete brand new petrol engines for the cost of re-conditioning your old diesel engine, and at the end you will still only have an old re-furbished engine.

SO IS THERE A WAY OF GETTING THE BEST OF BOTH WORLDS ???

At Swaymar we believe there is, for the smaller boat owner at least, and hopefully in time this may change. We have been doing development into LPG. As everyone knows when you convert a petrol engine to LPG the power drops BUT ! this is because you have converted a petrol engine to run on LPG and it is far from optimized, and that is being kind.

Competition quality components for LPG engines,

also showing pistons in block.

Most lead free petrol is around 95 octane, LPG is typically 115 octane, up there with aviation fuel. Got your attention yet? stick with me. If you discard the petrol element and build an engine to start and run exclusively on LPG it’s a whole different ballgame. By setting the compression ratio to suit LPG (and this would kill the pistons on petrol) designing the cam duration and lift curves to suit LPG and fitting special valves and valve seats in the heads (there is a little more, but we must keep a bit to ourselves to retain our edge) you end up with an engine which is only a little more expensive than a petrol engine 5%-10% (way cheaper than a diesel) but actually gives around 7% more power than its equivalent petrol version.

You now have an engine which initially does not cost much more than half the price of a diesel and when it does need a rebuild costs exactly the same as a petrol engine, it is one third the weight of a diesel and burns fuel at 65p per litre, around that’s £50.50 per hour, around half the price of petrol and £27.00 per hour less than diesel !

Many ski schools around the country are using LPG engines, but because they are converted petrol engines although they are saving huge amounts in running costs, if they were using purpose built engines developed purely for LPG, over a period of time they would save considerably more.

Now the bad news, I started by saying “the smaller boat owner could have the best of both worlds” this is unfortunately because to my knowledge there are very few marinas that dispense LPG, so for anyone with a larger boat on a mooring this solution unfortunately is not an option at the moment. However for anyone who has a boat up to about 22/23 feet that lives on a trailer, this is a perfect solution, replace the fuel tank with an LPG fuel tank and fit a purpose built LPG engine and every time you take your boat out for the day pull into the garage on the way down, fill her up with LPG at 65p per liter and have fun while making diesel boats look expensive.

Swaymar Phantom Series Petrol Engines

Fitted with Swaymar Phantom Series 496 petrol engines exclusively designed and built for the marine requirement of huge low end power combined with good fuel economy

496 Phantom Series Specifications

- Heavy duty steel crankshaft - Increases strength & safety margin

- Forged con-rods with NASA aerospace quality bolts - Increases strength & safety margin

- Forged aluminium competition quality pistons - Increases strength & safety margin

- All fully balanced to less than +/- 0.5 gram - massively reducing engine wear and vibration

- Gas-flowed cylinder heads - Increasing BHP & top speed

- Light reshaping of the combustion chamber - Gives more low end torque

- Specially developed Plasma Nitrided marine camshaft - Delivers more torque at lower RPM

- Increased compression ratio to 9.5:1 - Increasing fuel efficiency

- Duplex gears - Increase reliability

- Up-rated oil delivery system - Increase longevity

- Roller rockers - Greatly Increases valve and valve guide life in severe environments

- & much much more (full spec on request).